- Home

- About

- Products

- Applications

- News

- Contact

| Availability: | |

|---|---|

| Quantity: | |

EoncredGroup

| Product Name | China Market Hot Sale Flower Stand Film Faced Plywood |

| Material | Poplar,Hardwood,Birch,Combi.etc. |

| Thickness(mm) | 1.6mm-30mm |

| Density(kg/m3) | 500-700 according to different wood species |

| Face & back | Black,Brown,imported Dynea film,other colors are available, smooth,anti-slip,Marineplex,Hexa pattern,Fanera,etc. |

| Glue Type | Phenolic WBP,Melamine WBP,MR |

| Application | Mold-scaffold platforms,roofing,flooring,walls,doors in vehicles, agricultural trailers,containers,advertising signs,stage,etc. |

| Pressing Process | One time hot pressed,two times hot pressed |

| Repeated times | 8-15(Poplar),15-25(Hardwood),30-50(Birch) |

▼OUR PRODUCT

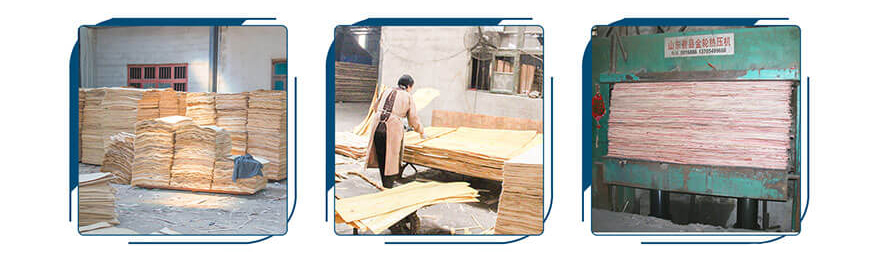

1. Planking → 2. Molding → 3. Prepressing → 4. Hot-pressing → 5. Deal Surface → 6. Sanding → 7. Laminated with Hot-pressing → 8. Sawing → 9. Checking (one by one) → 10. Printing (waterproof edge) → 11. Inter package →12. Outer package

▼OUR COMPANY

Linyi YIRUIDE Wood Co., Ltd, is a subsidiary of Eoncred Group, established in 1995, located in China’s largest wooden products manufacture base - Linyi city, have 3 factories, totally covered an area of 20000 square meters, with more than 200 employees.

Company focus on the production of Plywood, Film Faced Plywood, Fancy Plywood.

After decades of developing and upgrading, with high products quality and reasonable prices, the products sell well in more than 60 countries and regions, such as the Middle-East, Southeast Asia, South Asia, Europe, U.S.A, Africa, etc. Win the customer's wide welcome and trust.

The company has a high-quality QC team, in a rigorous, serious and responsible attitude, check the quality and ensure that each sheet is qualified.

We will serve you with the greatest enthusiasm, the most professional attitude, give you the most satisfied customer experience.

We are expecting to establish the mutual benefit business relationship with you.

Basic material of film faced plywood

The thickness of the substrate is between 0.3-0.5 mm. The thickness of the substrate of general well-known brands is about 0.5 mm.

First grade

The aluminum-magnesium alloy also contains some manganese. The biggest advantage of this material is its good oxidation resistance. At the same time, because of the manganese content, it has certain strength and rigidity. The performance of aluminum processing in the Southwest Aluminum Plant in China is the most stable.

Second grade

Aluminum-manganese alloy, the strength and rigidity of the material is slightly better than aluminum-magnesium alloy. But the oxidation resistance is slightly lower than aluminum-magnesium alloy. If the protective treatment is carried out on both sides, it basically solves the disadvantage that its oxidation resistance is not as good as that of aluminum-magnesium alloys. The aluminum processing performance of domestic West Aluminum and Ruimin Aluminum is most stable.

Third grade

Aluminum alloy, the alloy has less manganese and magnesium content. Therefore, its strength and rigidity are significantly lower than aluminum-magnesium alloy and aluminum-manganese alloy. Because it is soft and easy to process, as long as it reaches a certain thickness, it can basically meet the most basic flatness requirements of smallpox. But its oxidation resistance is obviously not as good as aluminum-magnesium alloy and aluminum-manganese alloy. Moreover, it is easily deformed during processing, transportation and installation.

Fourth grade

Ordinary aluminum alloy, the mechanical properties of this material are not stable.

Fifth grade

Recycling aluminum alloy. The raw material of this kind of plate is aluminum processing factory. The aluminum ingot is melted and tied into aluminum plate, and the chemical composition is not controlled at all. Due to the out-of-control chemical composition, the performance of these materials is extremely unstable, leading to serious unevenness of the product surface, product deformation, and easy oxidation.

In the use of new materials, there are also cases where electro-galvanized sheets are used as base materials for film-coated sheets.

If you want to buy film faced plywood,please contact EONCRED.

1. To ensure the products to meet the quality standards

2. To ensure the goods to be inspected piece by peice and delivered on time.

3. To provide warm and friendly service and after-sales service.

4. To reply you within 4 hours at the latest.

5. To guarantee the reliable quality and professional service,you will find that importing directly from us Eoncred is so easy and simple as you buy from local supplier.

▼FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

| Product Name | China Market Hot Sale Flower Stand Film Faced Plywood |

| Material | Poplar,Hardwood,Birch,Combi.etc. |

| Thickness(mm) | 1.6mm-30mm |

| Density(kg/m3) | 500-700 according to different wood species |

| Face & back | Black,Brown,imported Dynea film,other colors are available, smooth,anti-slip,Marineplex,Hexa pattern,Fanera,etc. |

| Glue Type | Phenolic WBP,Melamine WBP,MR |

| Application | Mold-scaffold platforms,roofing,flooring,walls,doors in vehicles, agricultural trailers,containers,advertising signs,stage,etc. |

| Pressing Process | One time hot pressed,two times hot pressed |

| Repeated times | 8-15(Poplar),15-25(Hardwood),30-50(Birch) |

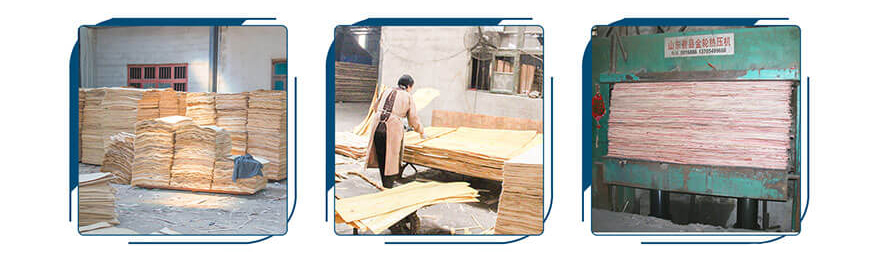

▼OUR PRODUCT

1. Planking → 2. Molding → 3. Prepressing → 4. Hot-pressing → 5. Deal Surface → 6. Sanding → 7. Laminated with Hot-pressing → 8. Sawing → 9. Checking (one by one) → 10. Printing (waterproof edge) → 11. Inter package →12. Outer package

▼OUR COMPANY

Linyi YIRUIDE Wood Co., Ltd, is a subsidiary of Eoncred Group, established in 1995, located in China’s largest wooden products manufacture base - Linyi city, have 3 factories, totally covered an area of 20000 square meters, with more than 200 employees.

Company focus on the production of Plywood, Film Faced Plywood, Fancy Plywood.

After decades of developing and upgrading, with high products quality and reasonable prices, the products sell well in more than 60 countries and regions, such as the Middle-East, Southeast Asia, South Asia, Europe, U.S.A, Africa, etc. Win the customer's wide welcome and trust.

The company has a high-quality QC team, in a rigorous, serious and responsible attitude, check the quality and ensure that each sheet is qualified.

We will serve you with the greatest enthusiasm, the most professional attitude, give you the most satisfied customer experience.

We are expecting to establish the mutual benefit business relationship with you.

Basic material of film faced plywood

The thickness of the substrate is between 0.3-0.5 mm. The thickness of the substrate of general well-known brands is about 0.5 mm.

First grade

The aluminum-magnesium alloy also contains some manganese. The biggest advantage of this material is its good oxidation resistance. At the same time, because of the manganese content, it has certain strength and rigidity. The performance of aluminum processing in the Southwest Aluminum Plant in China is the most stable.

Second grade

Aluminum-manganese alloy, the strength and rigidity of the material is slightly better than aluminum-magnesium alloy. But the oxidation resistance is slightly lower than aluminum-magnesium alloy. If the protective treatment is carried out on both sides, it basically solves the disadvantage that its oxidation resistance is not as good as that of aluminum-magnesium alloys. The aluminum processing performance of domestic West Aluminum and Ruimin Aluminum is most stable.

Third grade

Aluminum alloy, the alloy has less manganese and magnesium content. Therefore, its strength and rigidity are significantly lower than aluminum-magnesium alloy and aluminum-manganese alloy. Because it is soft and easy to process, as long as it reaches a certain thickness, it can basically meet the most basic flatness requirements of smallpox. But its oxidation resistance is obviously not as good as aluminum-magnesium alloy and aluminum-manganese alloy. Moreover, it is easily deformed during processing, transportation and installation.

Fourth grade

Ordinary aluminum alloy, the mechanical properties of this material are not stable.

Fifth grade

Recycling aluminum alloy. The raw material of this kind of plate is aluminum processing factory. The aluminum ingot is melted and tied into aluminum plate, and the chemical composition is not controlled at all. Due to the out-of-control chemical composition, the performance of these materials is extremely unstable, leading to serious unevenness of the product surface, product deformation, and easy oxidation.

In the use of new materials, there are also cases where electro-galvanized sheets are used as base materials for film-coated sheets.

If you want to buy film faced plywood,please contact EONCRED.

1. To ensure the products to meet the quality standards

2. To ensure the goods to be inspected piece by peice and delivered on time.

3. To provide warm and friendly service and after-sales service.

4. To reply you within 4 hours at the latest.

5. To guarantee the reliable quality and professional service,you will find that importing directly from us Eoncred is so easy and simple as you buy from local supplier.

▼FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.