- Home

- About

- Products

- Applications

- News

- Contact

| Availability: | |

|---|---|

| Quantity: | |

EoncredGroup

| Product Name | 10mm 4x8 Black Film Faced Plywood for Construction |

| Material | Poplar,Hardwood,Birch,Combi.etc. |

| Thickness(mm) | 1.6mm-30mm |

| Density(kg/m3) | 500-700 according to different wood species |

| Face & back | Black,Brown,imported Dynea film,other colors are available, smooth,anti-slip,Marineplex,Hexa pattern,Fanera,etc. |

| Glue Type | Phenolic WBP,Melamine WBP,MR |

| Application | Mold-scaffold platforms,roofing,flooring,walls,doors in vehicles, agricultural trailers,containers,advertising signs,stage,etc. |

| Pressing Process | One time hot pressed,two times hot pressed |

| Repeated times | 8-15(Poplar),15-25(Hardwood),30-50(Birch) |

▼OUR PRODUCT

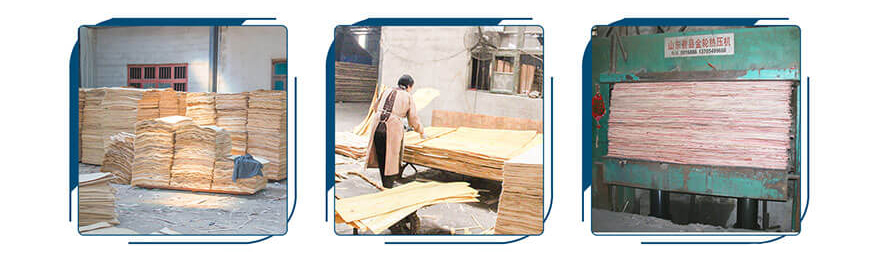

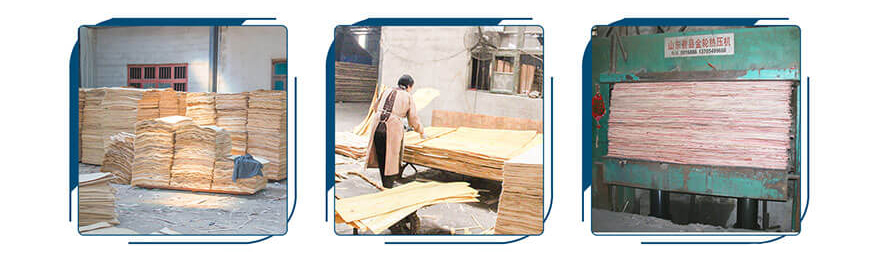

1. Planking → 2. Molding → 3. Prepressing → 4. Hot-pressing → 5. Deal Surface → 6. Sanding → 7. Laminated with Hot-pressing → 8. Sawing → 9. Checking (one by one) → 10. Printing (waterproof edge) → 11. Inter package →12. Outer package

▼OUR COMPANY

Linyi YIRUIDE Wood Co., Ltd, is a subsidiary of Eoncred Group, established in 1995, located in China’s largest wooden products manufacture base - Linyi city, have 3 factories, totally covered an area of 20000 square meters, with more than 200 employees.

Company focus on the production of Plywood, Film Faced Plywood, Fancy Plywood.

After decades of developing and upgrading, with high products quality and reasonable prices, the products sell well in more than 60 countries and regions, such as the Middle-East, Southeast Asia, South Asia, Europe, U.S.A, Africa, etc. Win the customer's wide welcome and trust.

The company has a high-quality QC team, in a rigorous, serious and responsible attitude, check the quality and ensure that each sheet is qualified.

We will serve you with the greatest enthusiasm, the most professional attitude, give you the most satisfied customer experience.

We are expecting to establish the mutual benefit business relationship with you.

The film faced plywood is a temporary supporting structure, which is made according to the design requirements, so that the concrete structure and components are formed according to the specified position and geometric size, maintain their correct position, and bear the weight of the film faced plywood and the external load acting on it. The purpose of the film faced plywood is to ensure the quality and safety of the concrete project, speed up the construction progress and reduce the cost of the project.

Advantages of film faced plywood:

1.high speed

The maximum weight of film faced plywood is 35-40KG, and the entire system can be easily set up with only one person. It is easy to assemble, just simply rotate the nylon handle to 90 degrees, and the entire system can be firmly assembled. The modular template is assembled or filled with water. No installation team or other processing is required when mud.

2.Easy to clean

Cement does not adhere to the plastic, so it is very easy to remove the module. You can clean the surface of the module with water only, without worrying about corrosion.

3. Convenient storage

The film faced plywood can be completely disassembled, and it is not necessary to store it in a dry environment.

4. Good site operability

The module can be quickly disassembled. Because of its light weight and quick installation, no crane is required on the engineering site.

5.recycle

Modular template is very economical, because compared with traditional template, it requires very little labor, and if it is cleaned and used properly, modular template can be recycled more than 10-20times

5. Good effect

The cement surface built with film faced plywood can be kept very smooth without additional cleaning work.

1. To ensure the products to meet the quality standards

2. To ensure the goods to be inspected piece by peice and delivered on time.

3. To provide warm and friendly service and after-sales service.

4. To reply you within 4 hours at the latest.

5. To guarantee the reliable quality and professional service,you will find that importing directly from us Eoncred is so easy and simple as you buy from local supplier.

▼FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

| Product Name | 10mm 4x8 Black Film Faced Plywood for Construction |

| Material | Poplar,Hardwood,Birch,Combi.etc. |

| Thickness(mm) | 1.6mm-30mm |

| Density(kg/m3) | 500-700 according to different wood species |

| Face & back | Black,Brown,imported Dynea film,other colors are available, smooth,anti-slip,Marineplex,Hexa pattern,Fanera,etc. |

| Glue Type | Phenolic WBP,Melamine WBP,MR |

| Application | Mold-scaffold platforms,roofing,flooring,walls,doors in vehicles, agricultural trailers,containers,advertising signs,stage,etc. |

| Pressing Process | One time hot pressed,two times hot pressed |

| Repeated times | 8-15(Poplar),15-25(Hardwood),30-50(Birch) |

▼OUR PRODUCT

1. Planking → 2. Molding → 3. Prepressing → 4. Hot-pressing → 5. Deal Surface → 6. Sanding → 7. Laminated with Hot-pressing → 8. Sawing → 9. Checking (one by one) → 10. Printing (waterproof edge) → 11. Inter package →12. Outer package

▼OUR COMPANY

Linyi YIRUIDE Wood Co., Ltd, is a subsidiary of Eoncred Group, established in 1995, located in China’s largest wooden products manufacture base - Linyi city, have 3 factories, totally covered an area of 20000 square meters, with more than 200 employees.

Company focus on the production of Plywood, Film Faced Plywood, Fancy Plywood.

After decades of developing and upgrading, with high products quality and reasonable prices, the products sell well in more than 60 countries and regions, such as the Middle-East, Southeast Asia, South Asia, Europe, U.S.A, Africa, etc. Win the customer's wide welcome and trust.

The company has a high-quality QC team, in a rigorous, serious and responsible attitude, check the quality and ensure that each sheet is qualified.

We will serve you with the greatest enthusiasm, the most professional attitude, give you the most satisfied customer experience.

We are expecting to establish the mutual benefit business relationship with you.

The film faced plywood is a temporary supporting structure, which is made according to the design requirements, so that the concrete structure and components are formed according to the specified position and geometric size, maintain their correct position, and bear the weight of the film faced plywood and the external load acting on it. The purpose of the film faced plywood is to ensure the quality and safety of the concrete project, speed up the construction progress and reduce the cost of the project.

Advantages of film faced plywood:

1.high speed

The maximum weight of film faced plywood is 35-40KG, and the entire system can be easily set up with only one person. It is easy to assemble, just simply rotate the nylon handle to 90 degrees, and the entire system can be firmly assembled. The modular template is assembled or filled with water. No installation team or other processing is required when mud.

2.Easy to clean

Cement does not adhere to the plastic, so it is very easy to remove the module. You can clean the surface of the module with water only, without worrying about corrosion.

3. Convenient storage

The film faced plywood can be completely disassembled, and it is not necessary to store it in a dry environment.

4. Good site operability

The module can be quickly disassembled. Because of its light weight and quick installation, no crane is required on the engineering site.

5.recycle

Modular template is very economical, because compared with traditional template, it requires very little labor, and if it is cleaned and used properly, modular template can be recycled more than 10-20times

5. Good effect

The cement surface built with film faced plywood can be kept very smooth without additional cleaning work.

1. To ensure the products to meet the quality standards

2. To ensure the goods to be inspected piece by peice and delivered on time.

3. To provide warm and friendly service and after-sales service.

4. To reply you within 4 hours at the latest.

5. To guarantee the reliable quality and professional service,you will find that importing directly from us Eoncred is so easy and simple as you buy from local supplier.

▼FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.